Featured, Insights • May 15, 2024

Finding Creative Solutions Using 3D Scanning Technology

Finding Creative Solutions Using 3D Scanning Technology

The concept of digitalization has profoundly transformed the landscape of the gas industry, ushering in a new era of innovation, efficiency, and sustainability. Digitalization entails the integration of advanced technologies and data-driven processes throughout the entire value chain of gas production, distribution, and consumption. By harnessing the power of digital technologies, the gas industry can optimize operations, enhance safety measures, and improve reliability.

Scanning Technology

Light Detection and Ranging—commonly referred to as lidar—scanning technology has revolutionized how the gas industry documents and records both new and existing equipment in various environments. Traditionally, capturing measurements of vast pipeline networks or complex industrial facilities could be time-consuming and labor-intensive, often taking days or weeks to complete with conventional documentation methods. However, lidar scanning technology streamlines this process by generating accurate, photorealistic 3D representations of environments or objects in minutes, even in challenging outdoor conditions.

To create this 3D scene, the scanner rotates and emits a laser beam that reflects off objects in the surrounding scene back to the scanner. When comparing the emitted laser beam to the received laser beam, a phase shift between the two can be used to calculate the exact distance from the object to the scanner. Within a range of up to 350 meters, the measurement is accurate down to millimeters. The scanner repeats this sending, receiving, and comparing millions of times and compiles these discrete measurements to build a 3D point cloud. Multiple 3D scenes can be stitched together to create a larger 3D model if the process is repeated in a different location. The scanner can generate 3D data that can be used to create countless drawings and records at a much quicker rate than manual processes.

Adopting lidar scanning technology brings many advantages to the gas industry. The efficiency of lidar scanning translates to reduced costs and minimized downtime for gas operations. With the ability to capture comprehensive data in a fraction of the time compared to traditional methods, Milhouse can optimize resource allocation and streamline project timelines. Overall, the integration of lidar scanning technology into Milhouse’s operations underscores the company’s commitment to innovation, efficiency, and safety in the gas industry.

Digital As-Builts

Accurate as-built documentation is essential in construction projects as it provides a comprehensive record of the site conditions on which design plans are based. Failure to accurately capture as-built data can lead to costly mistakes, including budget overruns, rework, and compromised quality. As-built software addresses these challenges by enabling engineers to efficiently create designs based on precise as-built data that seamlessly integrates with their CAD and BIM systems. After installing a new project, completing a scan to capture the as-built conditions has several advantages. The as-built scan lets engineers and operators close out action items quickly, maintaining process safety compliance. In addition, it saves time for future individuals looking to verify what was accomplished as part of a previous project or planning to make new modifications.

Milhouse’s approach to digital as-builts has many benefits. Firstly, enhanced collaboration among project stakeholders is facilitated by the seamless integration of digital as-builts into the design and construction workflow, fostering more transparent communication and alignment of objectives. With Milhouse’s 3D digital tools, stakeholders can quickly review the proposed project scope together without leaving their desks. Additionally, improved project management is achieved through more accurate and up-to-date documentation, enabling better decision-making and risk management throughout the budgeting, design, and construction processes. By reducing errors and discrepancies between design plans and actual site conditions, Milhouse minimizes the likelihood of costly rework and delays, ultimately leading to greater project efficiency and cost savings.

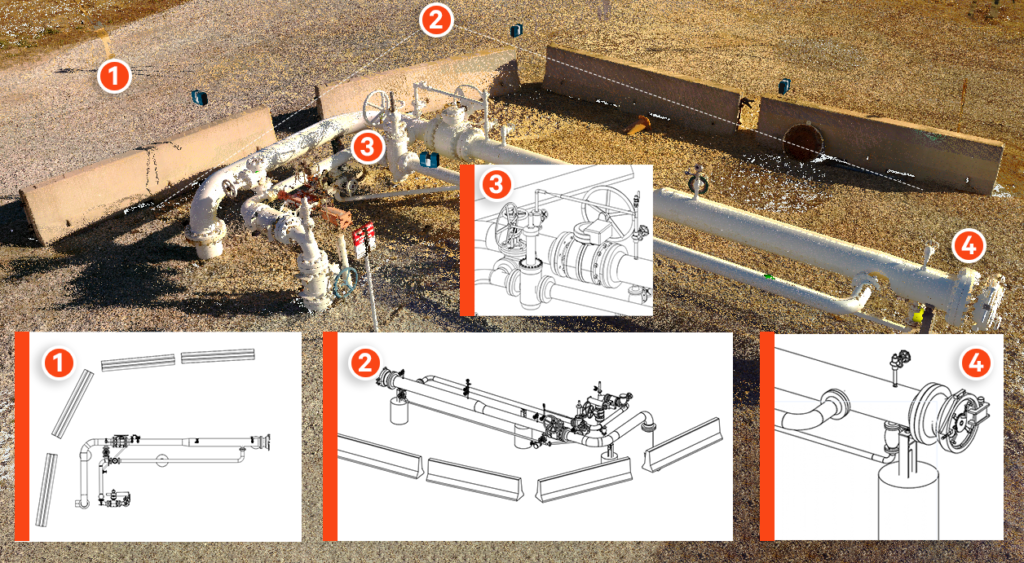

Having precise information about the current state of an environment is crucial for ensuring that proposed changes align with reality. In the gas industry, there often are many constructability challenges with new projects stemming from the complex physical layout of piping, instrumentation, and other installed process equipment. The 3D scan of an area can be used to identify potential obstructions and risks before installing the proposed design.

Milhouse’s adoption of advanced technologies for digital as-builts underscores its commitment to delivering high-quality construction projects with improved outcomes for its clients and stakeholders.

Anticipated Trends

We may realize numerous advancements as digitalization technologies improve and gain wider adoption. With more complete 3D scans captured, detailed virtual environments of gas facilities can be constructed. In the future, an engineer may take a full virtual facility tour. As they inspect various items, they can view maintenance or construction records linked to them through the virtual setting. In addition, the improved 3D models can serve as excellent training environments for future operations or maintenance personnel. Operators can drill many procedures at any time in the virtual facility, even though they typically perform them only during a scheduled outage or emergency. Equipped with more traceable, verifiable, and complete information, Milhouse can help gas industry leaders set a new standard of safety and reliability.

The digital transformation of gas networks represents a monumental shift towards a more efficient, safe, and sustainable future for the industry. Through the integration of advanced technologies such as lidar scanning and digital as-builts, companies like Milhouse are revolutionizing traditional processes through accuracy, efficiency, and safety. Milhouse’s commitment to innovation not only enhances it’s operational capabilities but also sets a new standard for excellence within the gas industry. As the digitalization journey continues to unfold, it is evident that embracing these transformative technologies will pave the way for a more resilient and sustainable gas industry poised to meet the challenges and opportunities of tomorrow. Read more about our expertise: https://bit.ly/3OHGwQU

Sources:

https://www.multivu.com/assets/52012/documents/52012-faro-focus-faq-original.pdf

https://www.faro.com/en/Resource-Library/Article/understanding-laser-scanners

https://downloads.faro.com/index.php/s/7JxXNmjrGQspwsb?dir=undefined&openfile=150745