Insights • January 21, 2025

Engineering and Construction Trends to Watch in 2025

Emerging trends and technologies are redefining the engineering and construction landscape for 2025. Sustainable building materials, wearing safety technology, artificial intelligence, and 3D scanning technology allow firms to refine their practices with increased precision and efficiency. These innovations are changing how engineers and general contractors conceptualize, design, and execute projects, helping firms create more intelligent solutions for clients in 2025 and beyond.

Sustainable Building Materials

As sustainability becomes an increased focus for the construction industry, firms seek new ways to integrate environmentally responsible practices. The green construction market is quickly growing, with projections indicating it will reach $774 billion by 2030. One of the main ways to advance sustainability goals is by using sustainable building materials during construction. Natural materials like wood, bamboo, slate, and stone offer traditional eco-friendly alternatives, while non-toxic synthetic materials like polyurethane, cellulose, isocyanate, and fiberglass provide modern sustainable solutions. New materials like natural fibers, self-binding concrete, and hydropower-compatible technologies are also gaining momentum. Selecting materials like these can help projects become Leadership in Energy and Environmental Design (LEED) certified. The industry’s gold standard for measuring green building achievements, this rating system evaluates projects across multiple categories, including materials and resources. Projects accumulate points based on their sustainable practices, with certification levels ranging from silver to platinum. Getting a LEED certification “enhances a building’s marketability and value, appealing to environmentally conscious tenants, investors, and stakeholders who prioritize sustainable practices.” By embracing sustainable material options and pursuing LEED certification, construction firms can strengthen their environmental impact, creating buildings that are forward-thinking and ecologically responsible.

Wearable Safety Technology

The health and safety of workers on job sites have always been a top priority in the engineering and construction industry. In 2025, wearable technology is making it easier than ever to implement safety protocols. PPE equipment like helmets with sensors can detect elevated CO2 levels, heat, and noise, while smart vests monitor workers’ body temperatures, heart rates, and hydration levels. Fatigue monitoring devices use EEG sensors to alert workers when they are becoming tired, which is helpful on construction sites where heavy tools and equipment are used. By collecting site safety data in real-time, wearable safety equipment helps effectively prevent potential accidents and protect workers.

Integrative Artificial Intelligence

Artificial Intelligence (AI) is revolutionizing the industry by offering new opportunities for efficiency, safety, and innovation. Advanced AI programs can analyze construction site photographs and video footage to identify safety risks, allowing for real-time detection of unsafe working conditions and potential accident sites. In the engineering sector, AI is driving improvements in systems and product design. By utilizing predictive analytics, companies can anticipate potential equipment failures, streamline operational processes, and reduce maintenance costs. A 2024 survey found that 67% of manufacturing companies are integrating AI into their operations, with many projecting a 10-15% reduction in operational expenses by 2025.

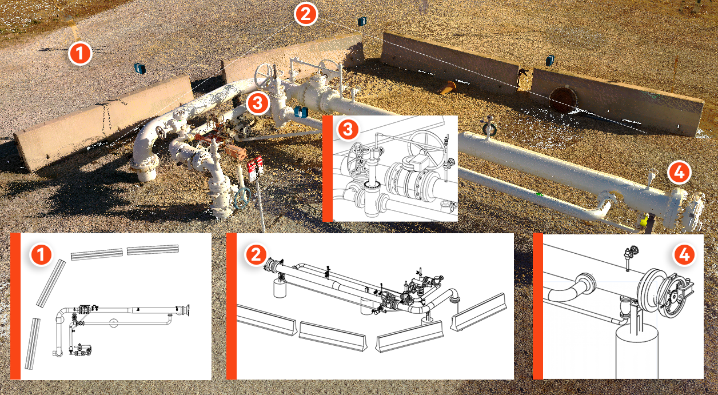

Digital Twins and Building Information Modeling (BIM)

Digital twinning using 3D scanning and Building Information Modeling (BIM) are emerging as popular technologies. A “digital twin” is the creation a virtual 3D model of a physical object or system, using simulation and machine learning to analyze and optimize projects. BIM extends this capability by adding dimensional layers: time (4D) for schedule simulation and cost (5D) for expense forecasting.

Milhouse employs digital twin technology, specifically Light Detection and Ranging (Lidar), in our engineering design services. Lidar can generate detailed 3D project representations in minutes, allowing us to develop more efficient plans for civil, structural, mechanical, and electrical projects. We also use 3D BIM tools and laser scanning to capture existing site conditions (as-builts) and create precise 3D models for use on engineering design projects.

Though Milhouse was an early adopter of 3D scanning technology, the engineering industry is catching up, and the market for these technologies is expanding rapidly. By 2029, digital twin usage is expected to increase by 60%, and the BIM market is projected to reach $14.8 billion.

As the engineering and construction industry moves into 2025, trends like sustainable building materials, wearable safety equipment, AI, and 3D scanning technology will be changing how firms operate by allowing them to improve project outcomes, reduce costs, and minimize safety risks. These trends will soon become industry mainstays, and firms that embrace them will be a catalyst for progress, innovation, and development in the second half of the decade.